CONCRETE LIFTING, LEVELING & SEAWALL REPAIR WITH FOAM

Welcome to Pinnacle Concrete Solutions Concrete Lifting, where we are the local authorities in handling all your lifting, leveling, and concrete repair requirements in Connecticut and neighboring states.

Concrete slabs that exhibit cracks, sunken areas, or unevenness can pose potential dangers and liabilities on your property. If your aim is to steer clear of safety hazards and restore the impeccable charm of your sidewalk, driveway, pool deck, parking lot, or any other concrete surface, our team of skilled technicians at Pinnacle Concrete Solutions is at your service.

As the foremost concrete lifting specialists in the region, we take pride in our vast experience, expertise, and cutting-edge equipment to level sunken concrete and restore it to a safe and stable position. Don’t delay; reach out to us today through a call or an online inquiry to schedule an on-site inspection and get your free cost estimate in Connecticut or the nearby areas.

SERVING RESIDENTIAL, COMMERCIAL, & INFRASTRUCTURE MARKETS

CONCRETE REPAIR BY PINNACLE CONCRETE SOLUTIONS

THE HAZARD

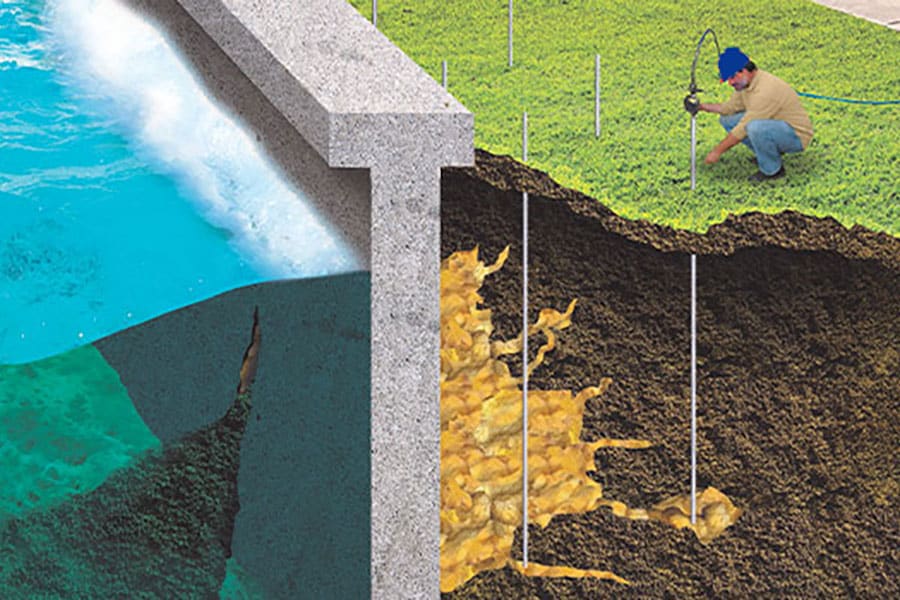

Mother nature’s influence makes the ground susceptible to contracting, expanding, and eventually failing. Lack of adequate support leads to concrete sinking, resulting in diminished curb appeal and creating both a liability and an unstable structure.

THE FIX

The process of concrete leveling entails gently raising the slab in small increments, ensuring a controlled lift and offering optimal protection for the concrete.

THE RESULT

This process involves using small injection holes and dries rapidly, offering a safe and effective solution that addresses your safety concerns while significantly extending the life of the concrete, ensuring it maintains its shape for many years to come.

WHY FOAM CONCRETE LEVELING

LASTS A LIFETIME!

Polyurethane undergoes a curing process, transforming into a solid and impermeable structure that firmly adheres to the concrete, making it highly resistant to fracture or failure.

SOIL STABILIZATION

Polyurethane is injected in its liquid form and reacts within the loosely, uncompacted soils to solidify and stabilize them effectively.

LESS INVASIVE

Pinnacle Concrete Solutions employs controlled injections through penny-size holes to efficiently and rapidly raise your concrete. In contrast, mudjacking necessitates much larger holes, sometimes up to 2 inches in size.

LIGHT WEIGHT

Polyurethane typically weighs approximately 2 pounds per cubic foot. On the other hand, mudjacking weighs over 100 pounds per cubic foot, exerting an enormous amount of pressure on an already compromised substructure.

IT SET’S FAST!

Polyurethane cures within minutes, allowing your concrete to be ready for use again as soon as we finish the job! In contrast, mudjacking can take several days before the concrete is ready for use.

ENVIRONMENTALLY SAFE

Our secure and environmentally-friendly foam forms a protective barrier between the soil and the concrete, providing resistance against moisture, liquids, insects, animals, further ground movement, and decay.

Concrete Damage Warnings & Indications

Connecticut often experiences concrete complications, primarily caused by soil conditions and seasonal changes. The crucial aspect is to identify the damage before it escalates into a hazardous and problematic situation, leading to costly repairs. Fortunately, modern technology allows for most concrete repairs to be efficiently addressed, ensuring the restoration of safety and longevity.

PINNACLE CONCRETE SOLUTIONS IS THE ANSWER TO ALL YOUR CONCRETE REPAIR NEEDS

Unlike traditional invasive concrete repair methods like mudjacking and concrete replacement, polyurethane foam injection employs high-density polymers to stabilize and lift concrete. This lightweight material requires smaller and fewer injection holes, making it an efficient alternative known as foam lifting – the latest and most advanced concrete repair method available.

Polyurethane foam injection offers both durability and lightness, providing support and lifting sunken concrete without adding extra weight. It presents an affordable and less invasive solution to address issues with sunken, cracked, and uneven concrete.

Most Polyurethane Foam Concrete Lifting and repair projects can be completed quickly and affordably, causing minimal disruption, with a one-day turnaround for a prompt return to service. Depending on the scope of your project, the concrete repair typically takes 1-2 hours. Injection holes are strategically drilled into the concrete slab(s) that require lifting.

The equipment is housed in a trailer rig, equipped with a long hose capable of reaching directly to the concrete slab location. Polyurethane foam is then injected under the slab, filling voids and raising it to the correct level. After the injection is complete, the hole is patched with polymer concrete or cement, rendering the concrete slab repaired and ready for immediate use.