WHAT YOU SHOULD KNOW ABOUT

USING POLYURETHANE INJECTION

SERVICING CONNECTICUT & SURROUND STATES

WHY FOAM CONCRETE LEVELING

LASTS A LIFETIME!

Polyurethane cures into a solid, forming an impermeable structure that firmly adheres to concrete, rendering it highly resistant to fractures or failures.

SOIL STABILIZATION

The process involves injecting polyurethane in its liquid form into the loosely arranged and uncompacted soils. Once injected, the polyurethane reacts, solidifying and stabilizing the soils effectively.

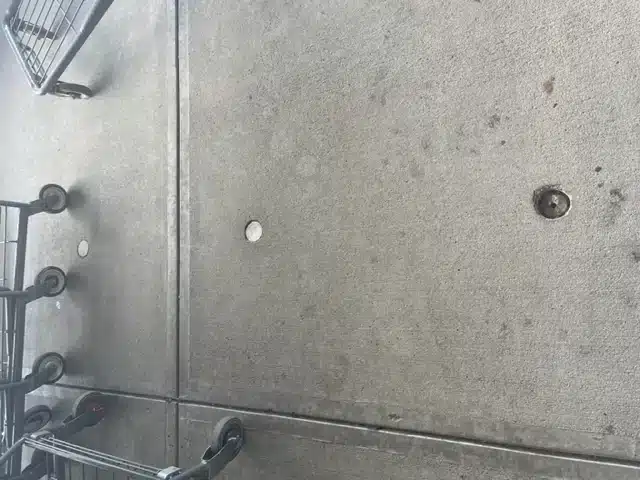

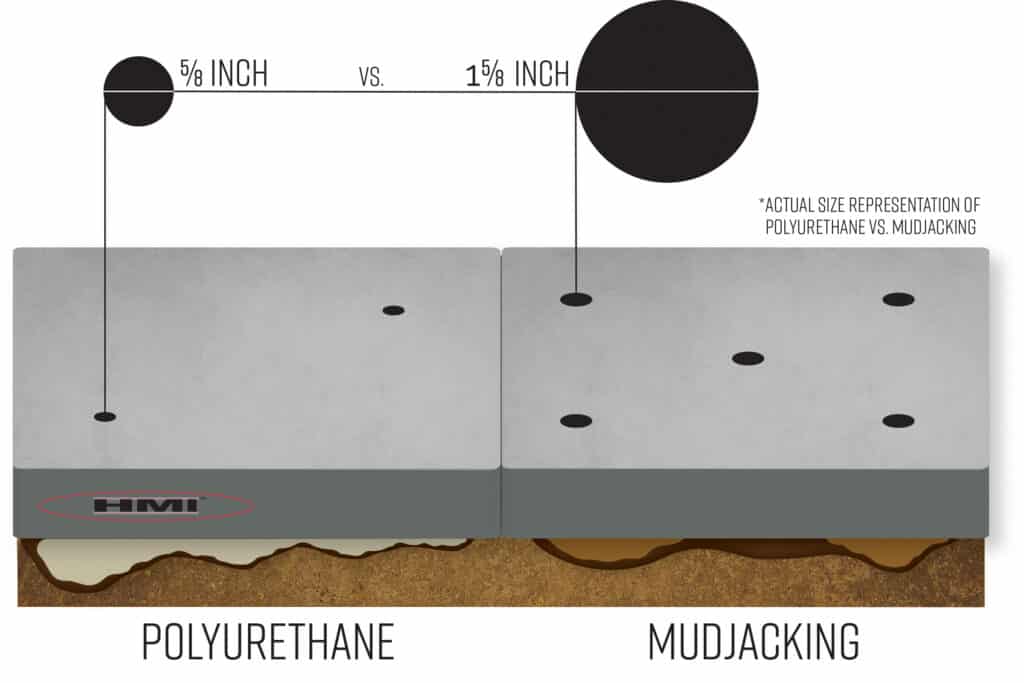

LESS INVASIVE.

At Pinnacle Concrete Solutions, we employ precise and controlled injections through penny-size holes to efficiently and swiftly elevate your concrete. Unlike mudjacking, which demands much larger holes of up to 2 inches, our method ensures a more effective and seamless concrete raising process.

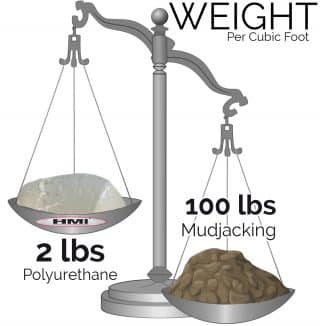

LIGHT WEIGHT

Polyurethane boasts a weight of approximately 2 pounds per cubic foot, making it a lightweight option. In contrast, mudjacking material weighs over 100 pounds per cubic foot, significantly increasing the load on an already burdened substructure. Opting for polyurethane helps avoid the excessive weight burden associated with mudjacking, ensuring a more favorable and manageable solution for your project.

IT’S FAST!

With Polyurethane, your concrete will cure within a matter of minutes, allowing you to use it again as soon as we complete the job! On the other hand, mudjacking can take days to cure fully, causing significant delays in the usability of your concrete surfaces. By choosing Polyurethane, you’ll experience rapid and efficient results, minimizing disruptions to your daily activities.

ENVIRONMENTALLY FRIENDLY

Our environmentally-friendly solution is not only safe but also made from recycled materials. It creates a protective barrier against moisture, chemicals, insects, rodents, additional ground movement, and erosion. By opting for our green solution, you can ensure the long-lasting preservation and safeguarding of your structures and surroundings.

WHY YOU SHOULD CHOOSE FOAM OVER MUDJACKING

The expense of polyurethane concrete raising equipment and the significantly higher cost of poly foam for concrete leveling compared to mudjacking raise an important question: Why should one choose polyurethane concrete raising over the traditional mudjacking method? To address this, we must consider and answer four other essential questions.

Why use polyurethane opposed to traditional mudjacking?

Polyurethane weighs approximately 2-4 pounds per cubic foot, in stark contrast to the 100-150 pounds per cubic foot weight of traditional mud. This significant difference in weight makes polyurethane material far less likely to overburden unstable soil, offering a more favorable and safer solution for various soil stabilization needs.

Does the finished job look better than traditional mud jacking?

Who wants their concrete raised using polyurethane foam?

The US Departments of Transportation have been increasingly favoring the use of polyurethane concrete lifting for addressing issues like sagging bridge approaches and removing dips in highways. The primary reason for this preference lies in the material’s lightweight characteristic, which ensures that the soil is not overburdened.

While conventional mudjacking will continue to exist for a considerable period, our experience indicates that the average consumer will always seek the most cost-effective way to fix settled concrete. Nevertheless, polyurethane concrete lifting has found its place as a reliable solution for raising slabs, especially in situations where a lightweight material is necessary. Its suitability for such scenarios ensures that polyurethane will remain a valuable option for these specific applications.

POLYURETHANE INJECTION

MUDJACKING

CONCRETE LIFTING, LEVELING

& SEAWALL REPAIR WITH FOAM

Discover the expertise of Pinnacle Concrete Solutions, your reliable local partner for all lifting, leveling, and concrete repair needs in Connecticut and surrounding states.

From cracks to sunken areas and uneven concrete slabs, these issues can present safety risks and liabilities on your property. Don’t allow hazards to mar the appeal of your sidewalk, driveway, pool deck, parking lot, or any other concrete surface. Our skilled technicians are ready to bring their expertise to restore and revitalize your concrete surfaces.

As a leading regional HMI Foam concrete lifting company, we possess the necessary experience, knowledge, and cutting-edge equipment to efficiently level your sunken concrete, restoring it to a safe and stable condition. Reach out to us through a call or online contact to schedule an on-site inspection and receive a free cost estimate for projects in Connecticut or nearby areas. Allow us to assist you in rediscovering the beauty and safety of your concrete surfaces.